How to calculate value chain emissions based on science

How businesses can measure their value chain emissions & guide their journey to net zero.

Value chains are drivers of climate change – and climate action.

Companies generate more than two-thirds of the planet’s emissions, and more than 90% of these emissions are produced in the value chain.

So if your company is looking to reduce its climate impact, logic says you should begin by making high-impact changes in your value chain. Add in that reducing emissions could also result in substantial cost reductions and efficiency gains, plus earning the trust of investors and employees, and you’ll likely want to get started as soon as possible.

The first step: figuring out where your value chain emissions are coming from.

What are value chain emissions?

Value chain emissions are in the Greenhouse Gas (GHG) Protocol’s “scope 3” emissions category.

Scope 3 includes all indirect emissions generated by resources not owned or controlled by the company but that the company indirectly impacts in its value chain; e.g. a company’s purchased goods and services, transportation, business travel, and waste produced during operations. (The full range of emission categories is described in the GHGP technical guidance for calculating scope 3 emissions).

Value chain emissions calculation methods

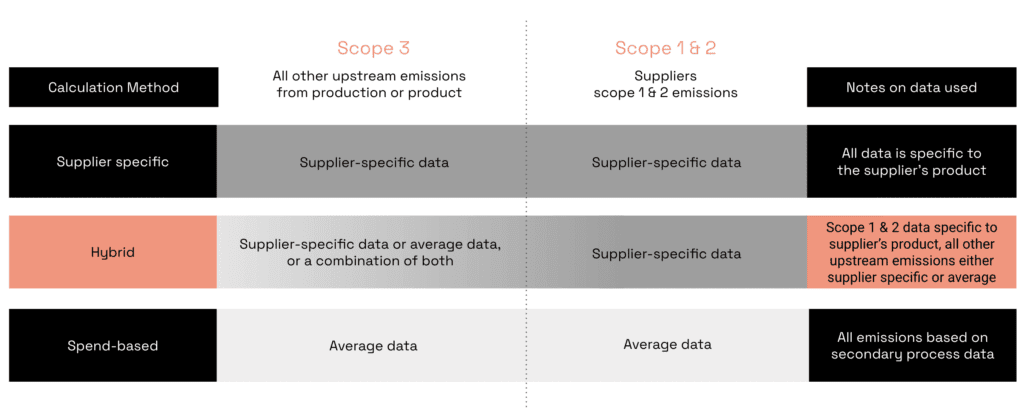

There are two main methods used to calculate value chain emissions: spend-based and activity-based.

The spend-based method takes the financial value of a purchased good or service and multiplies it by an emission factor – the amount of emissions produced per financial unit – resulting in an estimate of the emissions produced.

Since spend-based methods’ emission factors are built on the industry average greenhouse gas emissions levels, spend-based calculations can lack specificity. For example: if you buy a chair, a spend-based approach would only factor in that you bought a piece of furniture, and wouldn’t account for whether the chair was made of iron or wood.

The activity-based method solves that knowledge gap – though it requires you to collect additional data, both internally and from your suppliers. This method uses emissions data held by a company or given by its suppliers. The data – like the liters of fuel burnt by a truck – is multiplied by the emission factors of the activities, which gives the emissions estimate.

Gathering this data can be a complex process, especially for large businesses with thousands of suppliers. We produced a free, comprehensive guide to help large businesses engage their value chain in carbon measurement and reduction.

Though more cumbersome to determine, the results of these activity-based calculations show the impact of every single product or service your company buys, giving you more detailed and actionable insights to reduce value chain emissions.

How to manually calculate value chain emissions

If you’re looking to calculate your value chain’s carbon footprint for the first time, the Greenhouse Gas Protocol suggests beginning with the spend-based method.

This approach gives you a broad overview of your company’s emissions, allowing you to identify the biggest emissions sources of your carbon emissions.

To carry out a spend-based assessment you need three data points: your purchases, your suppliers, and the corresponding emission factors.

You can often export your purchase data from your company’s accounting system. Once you have your big spreadsheet of purchases, every purchase needs to be classified according to the industry of your suppliers. The UNSPSC is the most widely used industry classification standard, but you may use other standards if appropriate- This process takes time, and has to be done carefully, as manual entry of this type can often lead to errors.

The final step is to find industry emission factors for every supplier. This can involve a lot of searching, because there is no single resource that lists all the emissions factors – they can be found in government agencies, research institutes, company reports, and regulatory disclosures. Some of these sources are behind paywalls.

Technology makes calculating value chain emissions easier

Every hour spent doing manual calculations is an hour not spent reducing emissions. Emissions accounting technology can free up your time and help you achieve net zero emissions.

Normative’s emission accounting engine gathers thousands of data points and calculates your value chain emissions automatically – along with your scope 1 and scope 2 emissions, as well. All you need to do is upload your financial data; the accounting engine finds the corresponding emissions factors for your suppliers and, in a matter of seconds, displays your complete emissions profile, broken down by scope.

To make your carbon footprint even more precise, you can input activity data from your biggest emitters into Normative to further refine your emissions profile, in a hybrid model of spend-based and activity-based methods.

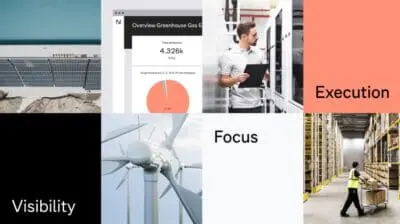

Normative’s data visualization dashboards highlight your emissions hotspots, and Normative sustainability experts help guide you toward net zero emissions with a customized reduction plan.

You can also track your climate footprint over time, proving the results of your reduction work to government bodies, investors, employees, and customers.

Companies all over the world are committing to achieving net zero emissions. Start your net zero journey today by beginning to calculate your value chain emissions!

Your value chain emissions – visualized & actionable

Normative’s emissions accounting engine shows you your company’s entire climate impact – including your value chain – and highlights the highest-impact actions you can take.